Production process

All our lamps are produced and assembled in Amsterdam where we share a workplace in the Houthaven with Defauwes Meubelmakerij and DM Interieurbouw. Our industrial CNC machine is also located here. Our DiBond aluminum table lamps are made on our smaller CNC machine and our larger DiBond aluminum wall lamps are milled by a partner in Amsterdam.

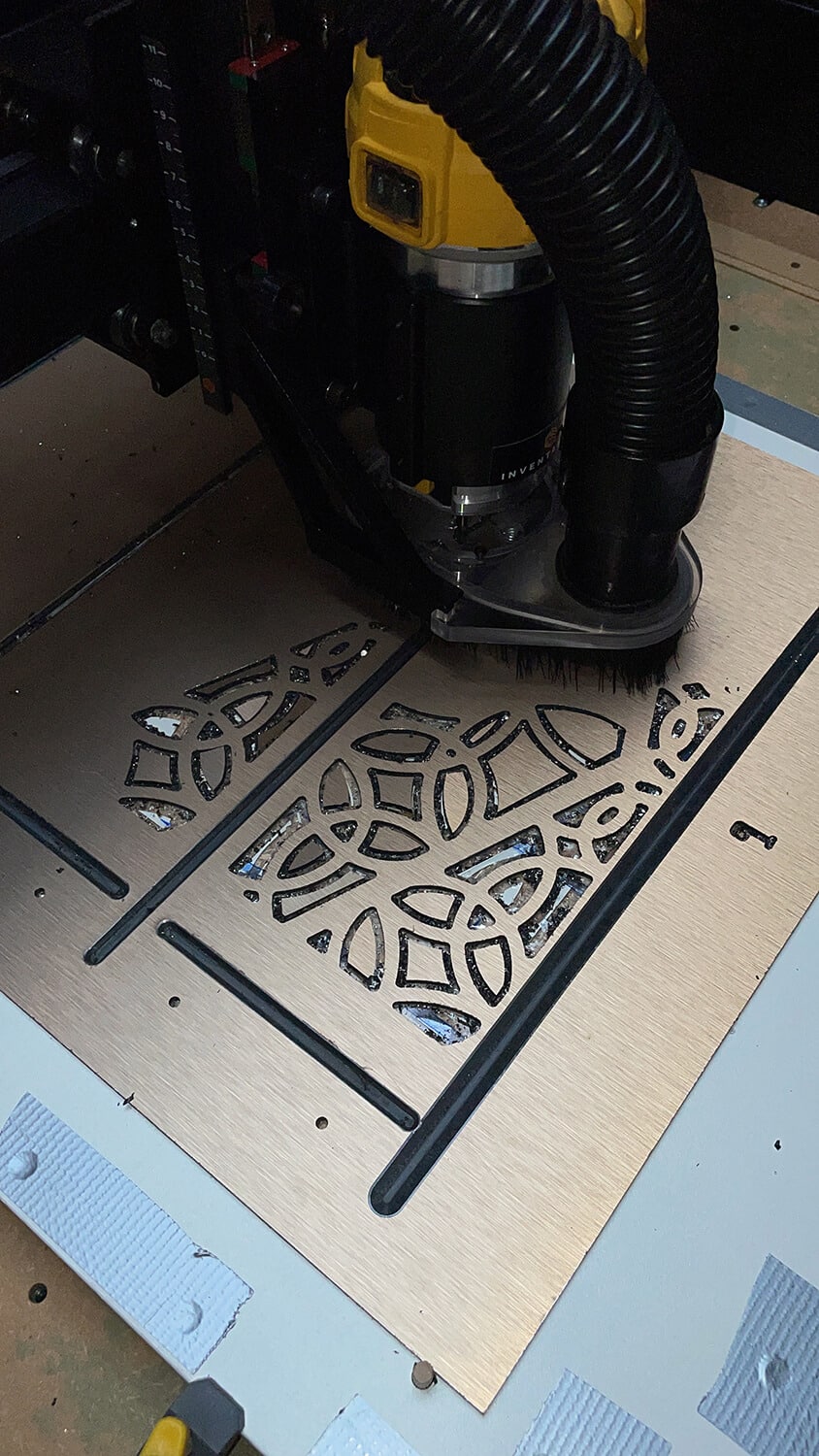

Production of our bamboo lamps

We make our bamboo lamps from 3-layer 20 mm side-pressed bamboo sheets from certified FSC suppliers such as Moso and BambooXL.

- We mill the bamboo on our own CNC machine

- We sand the bamboo for a smooth finish

- We protect the bamboo by applying a transparent base and 2 layers of Skylt transparent lacquer. (a high-quality sealant made in the Netherlands)

- We use high-quality Epistar LEDs that we cut and solder ourselves

- We cut and use high quality aluminum profiles for good heat management

- We assemble all lamps by hand using high quality transformers, controllers and other components.

Production of our DiBond table lamps

- All table lamps are milled on our own CNC machine and made from high-quality 3 millimeter DiBond sheets and 3 millimeter plexiglass diffusers.

- Each lamp is folded, assembled and packaged by hand in Amsterdam.

Production of our DiBond wall lamps

- All our larger DiBond wall lamps are milled by a partner in Amsterdam

- We use high-quality Epistar LEDs that we cut and solder ourselves

- We cut and use high quality aluminum profiles for good heat management

- We use high-quality 3 and 4 mm dibond aluminum (in various finishes) which we fold and assemble by hand

- All KuvaLights use high quality transformers, controllers and other components.